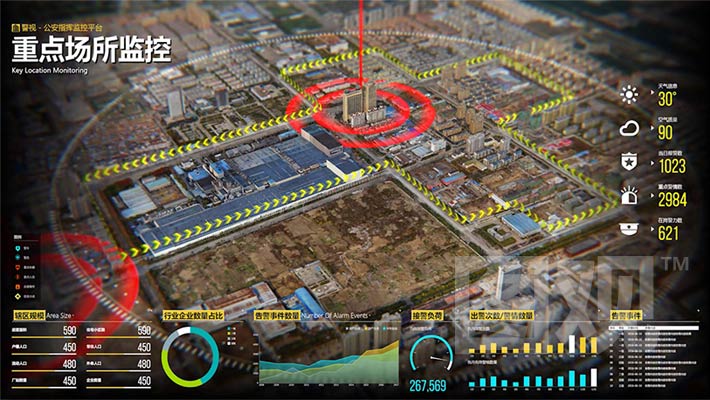

It supports monitoring of the location, distribution, and boundaries of industrial plants based on geographic information systems, integrating existing data resources in the factory, and conducting comprehensive monitoring and analysis of operational prompts in various fields such as production progress, facility operation and maintenance, energy efficiency management, storage and logistics, and security management, assisting managers in comprehensively grasping the operation status of the factory area.

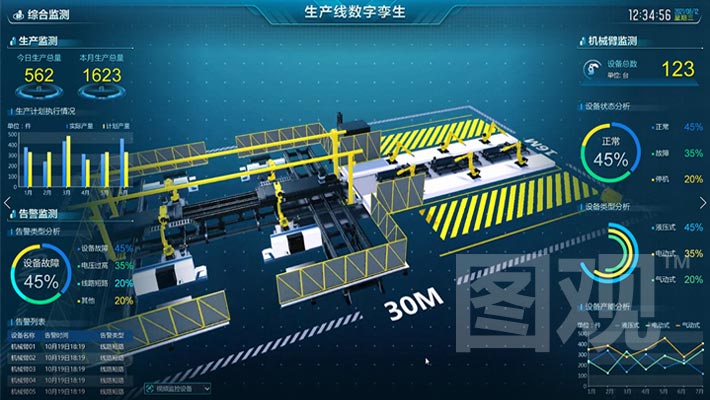

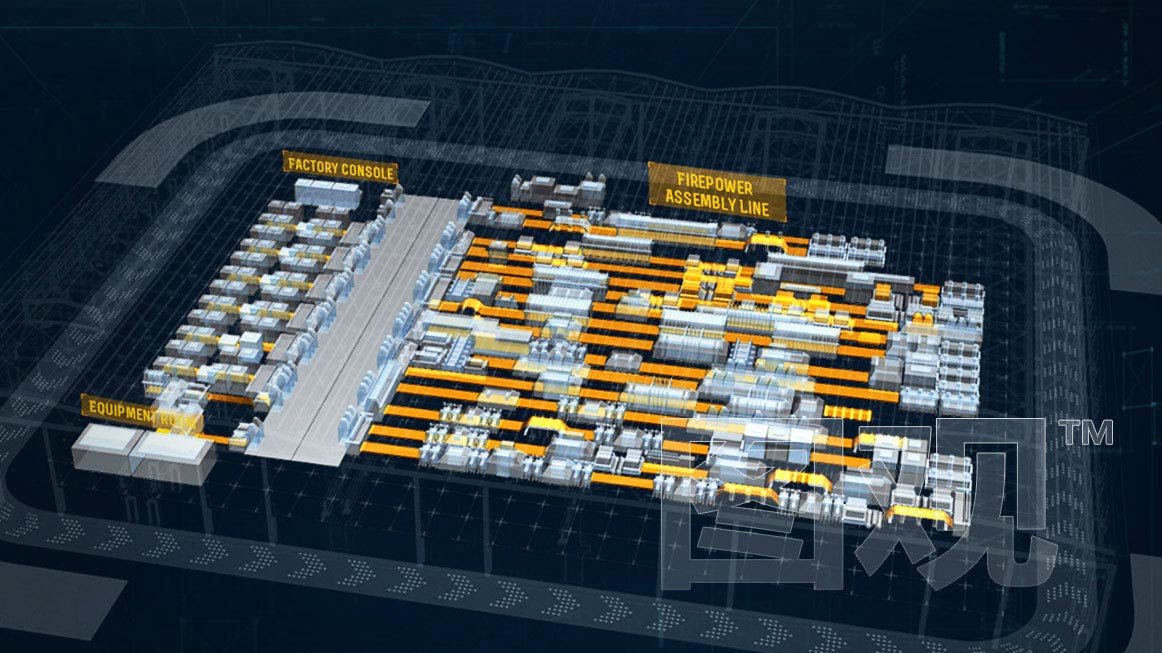

It supports reproducing various production lines, important equipment, operational processes, etc. based on real production line scenarios and monitoring and analyzing production processes, operating status, production progress, production data, etc., helping managers to grasp the production progress in real-time and improve production efficiency.

It supports reproducing the appearance, structure, and operation of equipment and facilities through 3D modeling. It can monitor the operating environment and status of equipment in real-time. It also supports real-time alarm notification for abnormal equipment operation, providing detailed information on equipment performance, repair records, video surveillance images, alarm details, etc. to assist managers in intuitively grasping the equipment's operating status.

It supports the integration of data from the factory's security and prevention management system and provides a comprehensive security monitoring map. It supports real-time monitoring of key areas, personnel, vehicles, alarm events, and other elements in the factory area. Security alarm events are quickly displayed and located, and surrounding surveillance videos can be accessed in real-time to assist managers in effectively enhancing the effectiveness of factory security control.

It supports integrating energy consumption data within the factory area and conducting real-time monitoring and multidimensional analysis of production and operation status in various sub-systems such as heating, water supply and drainage, energy consumption, and power supply. It supports energy consumption trend analysis and comprehensive evaluation of energy consumption indicators, helping managers to understand the energy consumption situation in the park in real-time, and providing powerful data basis for rational resource allocation and energy-saving emission reduction in the factory area.

It supports real-time monitoring of pedestrian and vehicle traffic, parking space usage, population density, etc. It can analyze and judge the results of facial recognition and license plate recognition and issue warnings for abnormal situations such as personnel or vehicles being delayed. It helps managers to grasp the flow of people and vehicles in the factory area in real-time and achieve convenient passage for personnel and vehicles.

Real-time rendering of all elements within the full scope and highest accuracy, delivering movie-grade visual effects to enhance user experience

Establishing an end-to-end integrated business loop of "intelligent early warning-intelligent perception-intelligent disposal-intelligent evaluation-intelligent improvement" for intelligent operation and maintenance.

Powerful cross-business platform integration capabilities that closely integrate data, technology, devices, and business needs to comprehensively empower user business applications.